Low Pressure Air Check Valves

Low pressure air check valves

Low pressure check valves are check valves used for low pressure applications. It include spring check valve, swing check valve, and wafer check valve. It allow fluids to flow in one direction only and prevent back-flow of fluids. Low pressure check valves are available in stainless steel material.

How much pressure does a check valve need?

The minimum upstream pressure required to operate the valve is called the cracking pressure, generally between 1 and 5 psi. Check valves are designed specifically with this number in mind.

What are the 5 types of check valves?

Most common types of Check valves are swing, lift (piston and ball), butterfly, stop and tilting-disk.

Does check valve reduce air pressure?

Check valves do not reduce pressure, they actually help maintain it. In the setup you describe, it might work. However you will DEFINITELY need another check valve on the outlet of the tank to prevent the high pressure flow from backwashing in through the bottom, since there is no shuttoff/float valve there.

Where should a check valve be installed?

Check valve can be installed in horizontal or vertical piping runs, with the flow running upward. Mounting for vertical installations is critical.

What is the difference between check valve and backflow preventer?

Check valves use a hinged plug that allows water to pass through the pipeline but blocks it from coming back. Backflow preventers, on the other hand, apply an increased amount of pressure on a pipe to ensure the water can only flow one way.

How much pressure does a check valve lose?

As a rule of thumb, the minimum pressure drop values for swing check valves are 0.5 psi and 2.0 psi for lift checks. The Guide for the Selection, Installation and Maintenance of Silent Check Valves by the Fluid Controls Institute recommends a 3 psi loss at normal flow for linear lift checks.

How far from pump should check valve be?

In submersible pump applications, the first check valve should be installed directly on the discharge head of the pump or maximum one pipe length (20 feet) above pump.

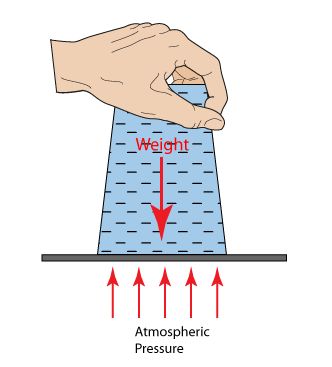

Do check valves hold pressure?

Vertical Check Valves: The valve is held shut by the spring until a sufficient amount of pressure is applied to push the spring back and open the valve. Pressure keeps the valve open and the spring compressed. Once pressure drops, the spring forces the disc into the seat to shut off the flow.

What are 3 types of check valves?

The three main types of check valves we offer are ball, piston, and stop check valves.

What is the best type of check valve?

Swing check valves are the most common check valves. They are inexpensive and as they are automatic they do not require any external power or control to operate – only the flow direction determines the valve operation.

What is the difference between PSV and PRV?

While the term PRV is sometimes used interchangeably with PSV, there is a difference between the two. A PRV opens gradually in relation to the pressure, while a PSV is opened suddenly once the pressure hits a certain level in order to avoid over pressurization and a potential process safety incident.

Do check valves restrict air flow?

Yes they do as that is their purpose. They restrict the flow in one direction 100%. in the reverse direction (open) they will never get to 100& flow as it takes a small amount of effort to shift the valve from the blocked direction to the flow direction.

Can you have too many check valves?

Several problems can arise from having multiple check valves in the system. The more check valves in a system, the more friction loss. A larger pump may even be needed to compensate for the additional friction loss. Multiple check valves can possibly cause contamination of the water.

What is the difference between a control valve and a check valve?

The check valve supplies free flow in one direction while restricting flow in the returning direction. Flow control valves installed into the work ports of a cylinder, for example, can be installed to restrict flow either going into or coming out of the cylinder port.

What happens if you install a check valve backwards?

Installation orientation If there isn't an arrow, examine the valve to ensure it is installed in the intended flow direction. If the valve is installed backward, media will not be able to move through the system, and the resulting pressure build-up can cause damage.

Should check valves be installed vertically or horizontally?

Not all styles of check valves function properly or are suitable for vertical flow directions. When installing a check valve, a horizontal line is always preferred, because it takes gravity out of the equation.

Do check valves go before or after a pump?

Check valves also protect the pumps from harm or leakage, so it makes for good practice to install check valves after the pump to prevent any backflow.

Where should a backflow preventer check valve be installed?

You should have your backflow prevention assembly installed inside an above-ground enclosure. It's the safest and most cost-effective place to put it. Installing your backflow preventer above ground in an outdoor enclosure allows you to protect your backflow preventer and maintain easy access to it.

When should check valves be used?

Check valves are generally installed in pipelines to prevent backflow. A check valve is basically a one-way valve, in which the flow can run freely one way, but if the flow turns the valve will close to protect the piping, other valves, pumps etc.

Post a Comment for "Low Pressure Air Check Valves"